Retired US Marine and law-enforcement special investigator completes his first custom fishing rod

PARK FALLS, WIS. (January 10, 2025) – James Tannahill was not in a good place when he retired from a military and law-enforcement career spanning more than 30 years.

“People don’t realize how far-reaching PTSD is,” the Mont Belvieu, Texas resident says. “The military and law-enforcement communities have the highest suicide rates of all occupations, but PTSD can impact almost anyone and have a variety of causes.”

Indeed, Tannahill experienced some trauma during his service as a US Marine, but it was the last five years of his professional career working as Special Investigator for the Texas Department of Family and Protective Services that did the most damage. “It took a toll on me,” the former college athlete says. “Aside from saving children, the job was not pleasant. The trauma piled up heavily from the things I saw and was forced to deal with.”

Tannahill sought and received care and treatment from the VA a short time after his retirement. “Thanks to my team at the VA, I’ve done a pretty good job improving my spiritual, mental, and physical health,“ he says, adding that his doctors have gone “above and beyond” in their commitment to Tannahill’s treatment. “The quality of care I have received at the Houston VA has been amazing.”

Tannahill’s doctors recommended he start a new hobby – something he cared about that would help hold his attention and focus . “I already had fishing,” Tannahill reports, “but I saw a video on custom rod-building and it captivated me.”

Tannahill reached out to Rod Geeks – St. Croix’s rod blank business – and asked if they offered a military discount. “To my surprise, they wanted to hear more about my story and thought it would be interesting for other people who are thinking about getting into rod building to follow my journey as a beginning rod builder,” he says. “So, they asked what kinds of rods I wanted to build and graciously sent me a couple blanks while putting me in contact with Bill Falconer at Anglers Resource. Bill not only helped me out with the other materials and components I needed, but also offered friendship and support in my journey.”

After taking a rod-building class where he learned some skills and made some additional friends, Tannahill went to work on his first rod, a 7’3” medium power inshore saltwater spinning model designed for popular popping-cork techniques employed along the Texas Gulf Coast. “The Rod Geeks XC33 blank that St. Croix sent me was beautiful,” he says. “Their hybrid carbon and glass X-Comp Series blanks are designed to be durable and lightweight with tons of power for inshore fishing. And since it comes from St. Croix, you know you are starting your build with the best.”

Every hobby takes varying degrees of capital, and while he received help from St. Croix and Anglers Resource with the blank and components, Tannahill ended up purchasing a Flex Coat Power Rod Wrapper / Finisher & Guide Alignment Tool. “It was definitely an investment, but it’s an amazingly well-designed and built tool that I’d highly recommend to anyone who wants to get into the hobby.”

“During my rod-building class, I learned that every rod blank has a spine – one side that is actually stiffer,” Tannahill says. “Finding the spine on the blank is important because you want the spine on top so the rod performs the best. It seems complicated, but it was easy. I learned how to do it at my rod-building class and it turns out I’m pretty good at it! I was able to help a few other people in the class learn how to do it. One you mark the spine you are ready to start building.”

Tannahill attacked the handle and reel seat first. “I opted for a traditional full-cork handle,” he says. “The cork comes in rings that you need to ream out in the center to place on the blank… foregrip first, then the reel seat, then the main handle, then the butt. The rings can get a little off center as you place them on, but it’s no big deal. I just rotated each one a quarter turn so the cork material stayed fairly centered along the blank. Then you glue everything together, clamp it, let it all dry and then sand it all down until you are happy with the shape.”

Then came the guides.

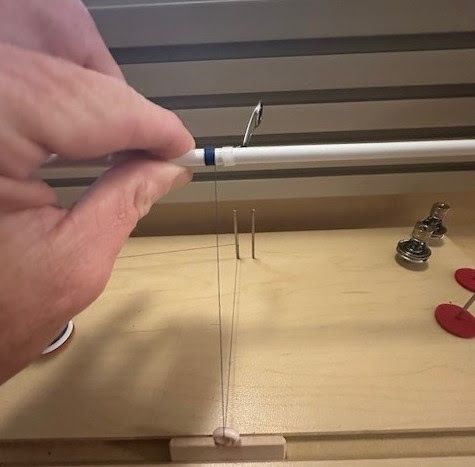

“I think figuring out the guide spacing and placement would be one of the more significant challenges for a beginning rod builder,” Tannahill says. “But I was lucky and had a lot of help and guidance from Aaron and Bill at Angler’s Resource. I went with black stainless-steel guides with SiC (silicon carbide) inserts. Once you know the spacing, you place them and wrap them on the blank with thread. I marked all their locations, then placed and wrapped two at a time. You need to make sure they follow the spine – on the spine side for casting rods and on the soft side opposite the spine for a spinning rod like I was building.”

Tannahill says the thread wrapping was definitely his favorite part of the entire process. “Learning how to start and finish the wraps is the hard part, but my rod-building class gave me the information and confidence I needed. The rest of the process is easy. I have some OCD, so I really took my time with them. I think that’s why I like it so much,” he says. “I start my wraps exactly 1/16 of an inch from the foot of each guide so they all look uniform. I’m really happy with how they came out with the black thread – they look great with the black guides on the white blank – but I’m looking forward to practicing and doing some fancier wraps on future builds.”

After thread-wrapping the guides, it’s time to coat the wraps with epoxy. “I used Flex Coat and it was easier than I thought,” Tannahill reports. “Make sure to use a 50/50 ratio of the epoxy and the hardener. Again, with my OCD, I made sure I used the same amount of epoxy on each guide. I know it was the same because I weighed it! It came out great, and I was very happy with that part.”

After a few hours of drying, Tannahill received the reward of looking at his first completed fishing rod. He reflects on the experience and the initial hope that this new hobby would in some way help with his mental and emotional healing.

“I initially thought that the rod-building process itself would be good for me, and at this point I can confirm that it has been,” he says. “When I am building – no matter which part of the process it is – I find myself completely focused and immersed in the process. This has been incredible therapy for my PTSD. Every step is really an art form, and I can see how it allows people’s creativity to run wild. It has given me tangible confidence and also something to talk about and look forward to. It also teaches you to adapt and overcome.”

What Tannahill was not expecting were all the ancillary benefits – therapeutic aspects of the hobby outside of the physical rod-building process.

“I would recommend rod building to anyone with PTSD who also has an interest in fishing,” he says. I was pretty sure it was going to be good for me, but I’m about 150% better than my wildest expectation. I’ve learned that rod-building is more than a process – it’s an entire community full of interesting and creative people, many of whom are Veterans like me. I’ve made some real and meaningful connections and am grateful for that. I feel so good that I am currently exploring getting back into the workforce in the law-enforcement field – a gigantic step for me. And I’m seriously looking at making custom rod building and rod repair a side business. I have also talked to some other vets and we are thinking about starting a rod-building club. I’m back in the game.”

Rod building has taught James Tannahill that he can continue to help and inspire others. “That’s why I’m doing this,” he says. “If a complete layman like me can do this and enjoy this so much… and have success at it… I know others can too. I want to show what I learn but also share how building custom fishing rods can be a positive and therapeutic experience. If it helps me, then it could also help other people suffering from PTSD.”

About Rod Geeks

Brought to you by the people, expertise, and experience of St. Croix of Park Falls, Inc., Rod Geeks has delivered handcrafted, high-performance fishing rod blanks to custom rod builders since 2014. Backed by nearly 75 years of experience in designing and building the best fishing rods in the world, we own and operate modern, state-of-the-art fishing rod factories in Park Falls, Wisconsin and Fresnillo, Mexico where we combine the best raw materials, equipment, technologies, expertise, and experienced craftsmanship to produce thousands of uncompromising fishing rods and blanks every week. Whatever your next adventure or project, trust Rod Geeks to provide a foundation for your passion and creativity that’s worthy of your talents.

About St. Croix Rod

Headquartered in Park Falls, Wisconsin, St. Croix has been proudly crafting the “Best Rods on Earth” for 75 years. Combining state-of-the-art manufacturing processes with skilled craftsmanship, St. Croix is the only major producer to still build rods entirely from design through manufacturing. The company remains family-owned and operates duplicate manufacturing facilities in Park Falls and Fresnillo, Mexico. With popular trademarked series such as Legend®, Legend Xtreme®, Avid®, Premier®, Imperial®, Triumph® and Mojo, St. Croix is revered by all types of anglers from around the world. The St. Croix Family of Brands includes St. Croix Rod, St. Croix Fly, SEVIIN Reels, and Rod Geeks.

Read the full article here